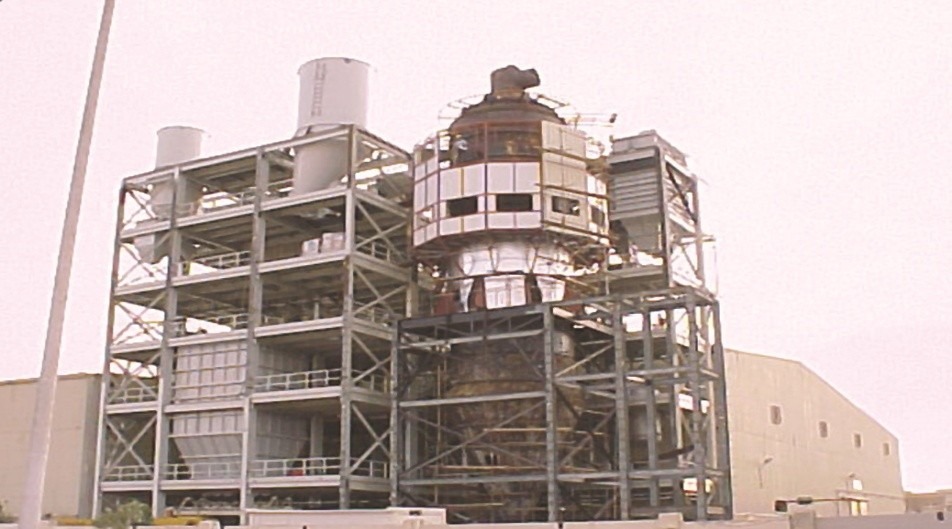

Food

& Agriculture

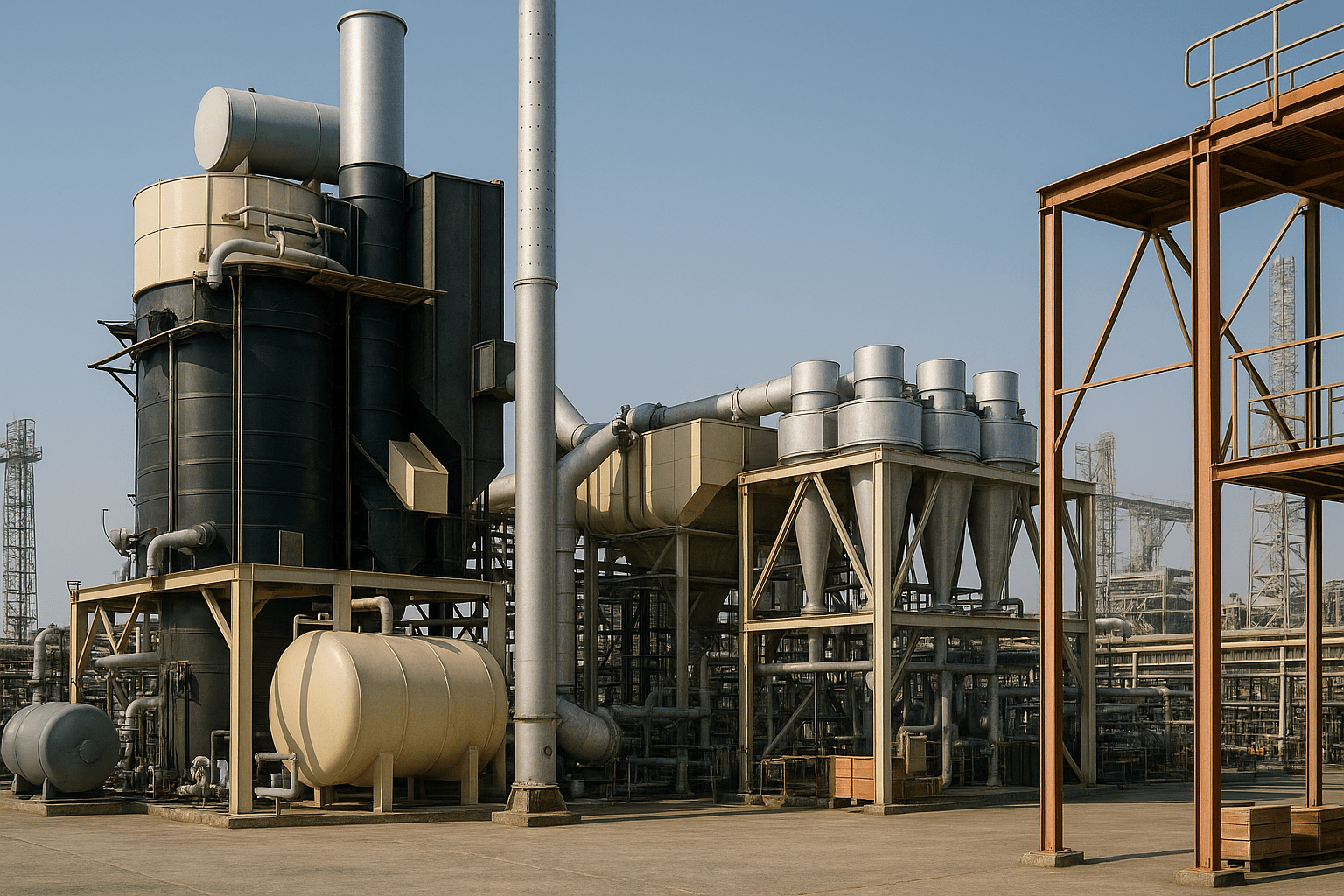

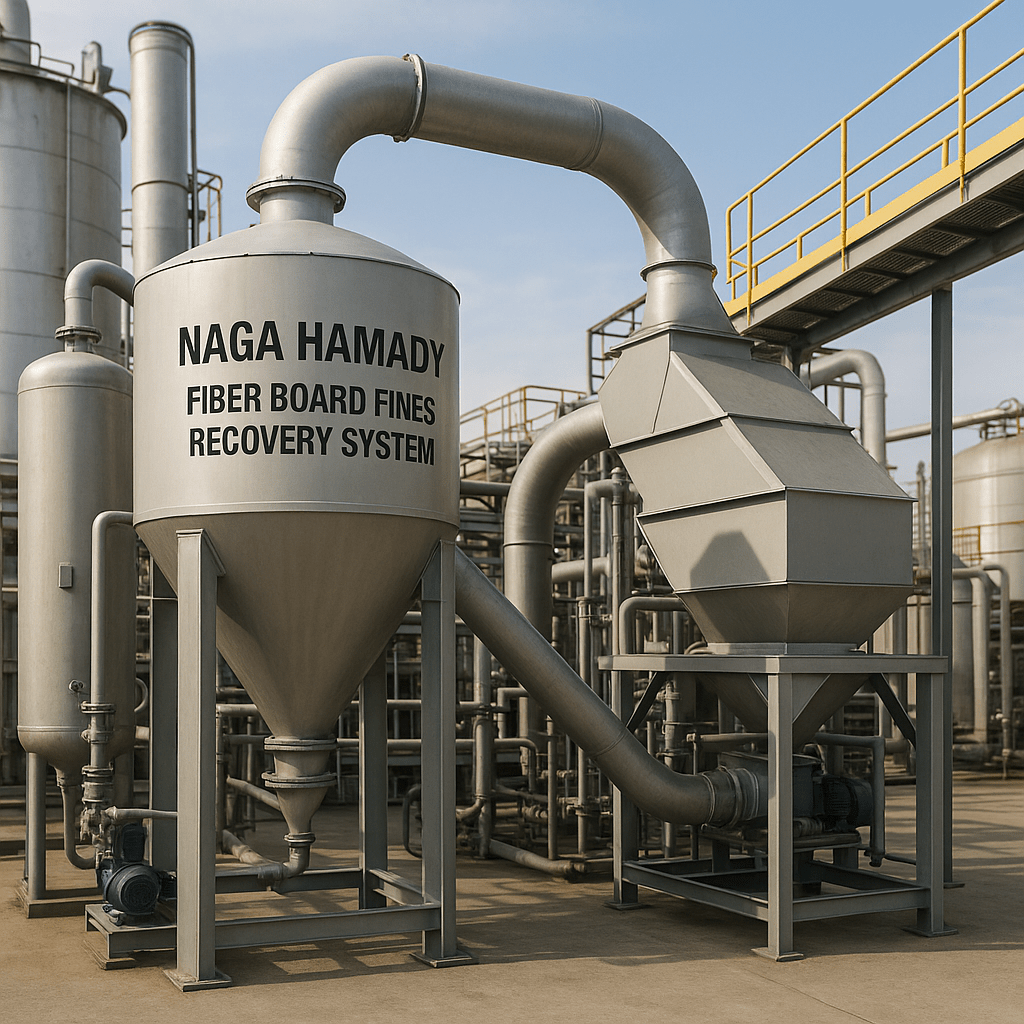

Naga Hamady for Fiber

Board

Fines Recovery System

Summary:

The Naga Hammadi Fiber Board Plant is a key industrial facility within Egypt’s wood-based panel sector, dedicated to producing medium-density fiberboard (MDF) from agricultural and wood residues. The plant has recently integrated a Fines Recovery System, a critical environmental and operational upgrade aimed at improving resource efficiency and reducing waste. This system captures fine particles generated during the fiberboard manufacturing process, reintegrating them into production or managing them sustainably. The enhancement reflects the company’s commitment to cleaner production, cost savings, and compliance with environmental standards.

Capabilities:

- Fines Particle Capture

Advanced filtration and cyclone systems to separate fine wood particles from air and process streams. - Material Recovery & Reuse

Collected fines are reused in MDF production or repurposed as fuel, reducing raw material waste and operating costs. - Dust & Emission Control

Significant reduction in airborne dust and particulate emissions, contributing to improved worker safety and air quality. - Energy Efficiency

The system enhances thermal efficiency by redirecting fine particles into energy recovery processes such as boiler fuel. - Compliance with Environmental Regulations

Meets local and international standards for dust control and waste management in industrial wood processing. - Operational Optimization

Improves overall process reliability by preventing fines accumulation in ducts and machinery, reducing downtime and maintenance needs.

Alex Flour Mill Company

Summary:

Alex Flour Mill Company is a leading flour milling enterprise based in Alexandria, Egypt, dedicated to delivering high-quality wheat flour products to serve the needs of bakeries, food manufacturers, and consumers across the region. With a deep-rooted commitment to food safety, product consistency, and customer satisfaction, Alex Flour Mill integrates modern milling technology with decades of experience to ensure excellence in every grain.

Capabilities:

High-Capacity Milling Lines

State-of-the-art milling machinery with advanced automation, capable of processing various types of wheat into multiple grades of flour.Strict Quality Control

Comprehensive testing procedures at every stage of production to ensure purity, consistency, and compliance with national and international food standards.Custom Flour Blending

Tailored flour specifications to meet the unique requirements of different clients including bakeries, pasta producers, and industrial food applications.Grain Storage & Handling

Modern silos and handling systems ensuring proper preservation of raw materials and streamlined production flow.Sustainable Operations

Environmentally conscious practices including dust control systems, waste reduction, and energy-efficient production methods.Reliable Distribution Network

Well-organized logistics and supply chain infrastructure for timely delivery throughout Alexandria and surrounding governorates.Research & Innovation

Continuous development of new blends and improved processes through a dedicated quality and R&D team.

Alex Seeds Company - Borg El-Arab

Summary:

Alex Seeds Company, located in Borg El-Arab, Egypt, is a specialized agribusiness company focused on the processing, packaging, and distribution of high-quality oilseeds and agricultural grains. Serving both domestic and export markets, the company plays a vital role in Egypt’s agro-industrial value chain. With modern processing facilities and a strong commitment to quality, food safety, and sustainability, Alex Seeds supports industries such as edible oil production, animal feed manufacturing, and agricultural supply.

Capabilities:

Oilseed Cleaning & Grading

Advanced machinery for cleaning, sorting, and grading oilseeds such as soybeans, sunflower seeds, cottonseed, and canola to meet industrial specifications.Seed Packaging & Bulk Handling

Flexible packaging solutions ranging from small retail bags to bulk containers for B2B and export clients.Storage & Preservation Facilities

Large-capacity silos and climate-controlled storage units that ensure seed quality, moisture control, and long-term preservation.Logistics & Export Readiness

Located near Alexandria’s major ports, the company is well-positioned for efficient local supply and international export operations.Quality Control & Testing Labs

On-site laboratory facilities ensure that each seed batch complies with safety, germination, and purity standards aligned with global norms.Support for Edible Oil Industry

Reliable source of raw oilseeds for crushers and refineries involved in the production of edible oils.Animal Feed Input Supply

Processing of seed byproducts (such as meal and husks) to serve animal feed manufacturers.Sustainable Agricultural Practices

Promoting responsible sourcing and processing with minimal waste and environmental impact.

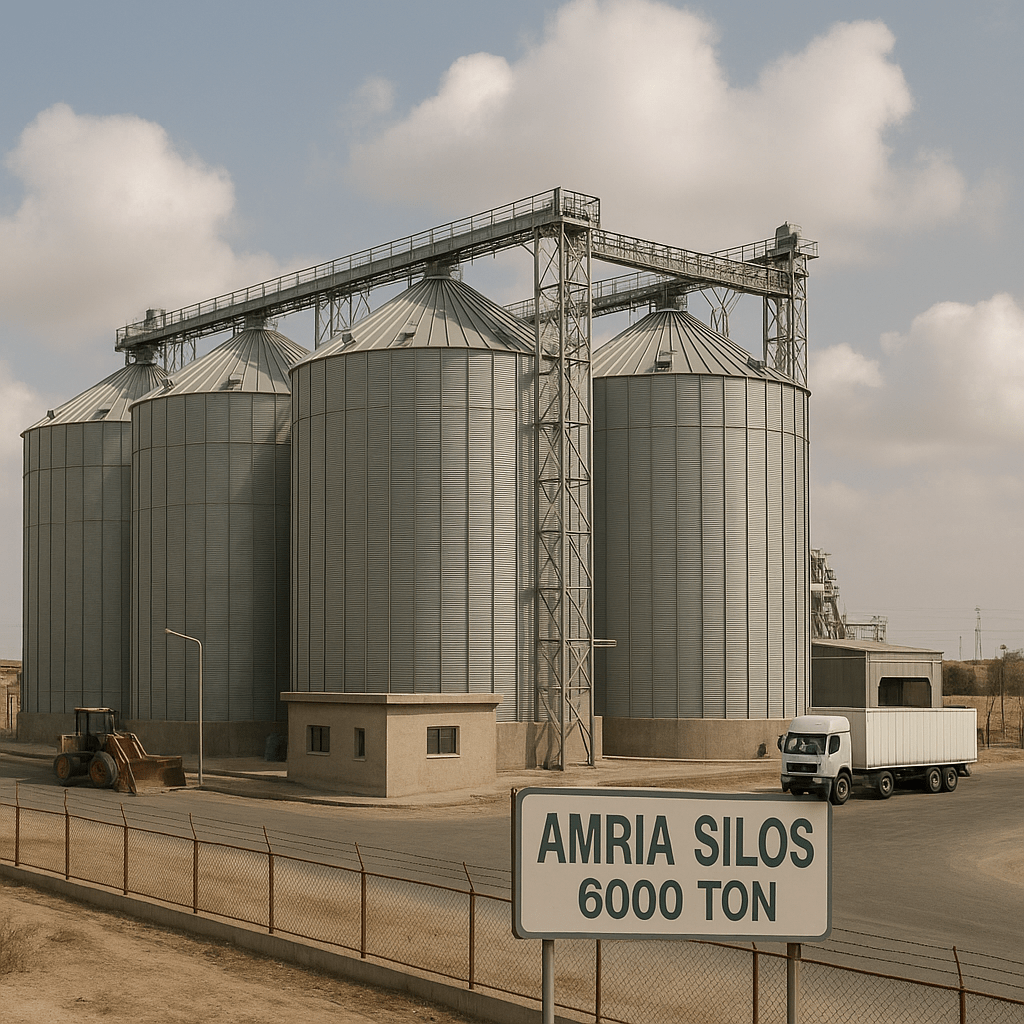

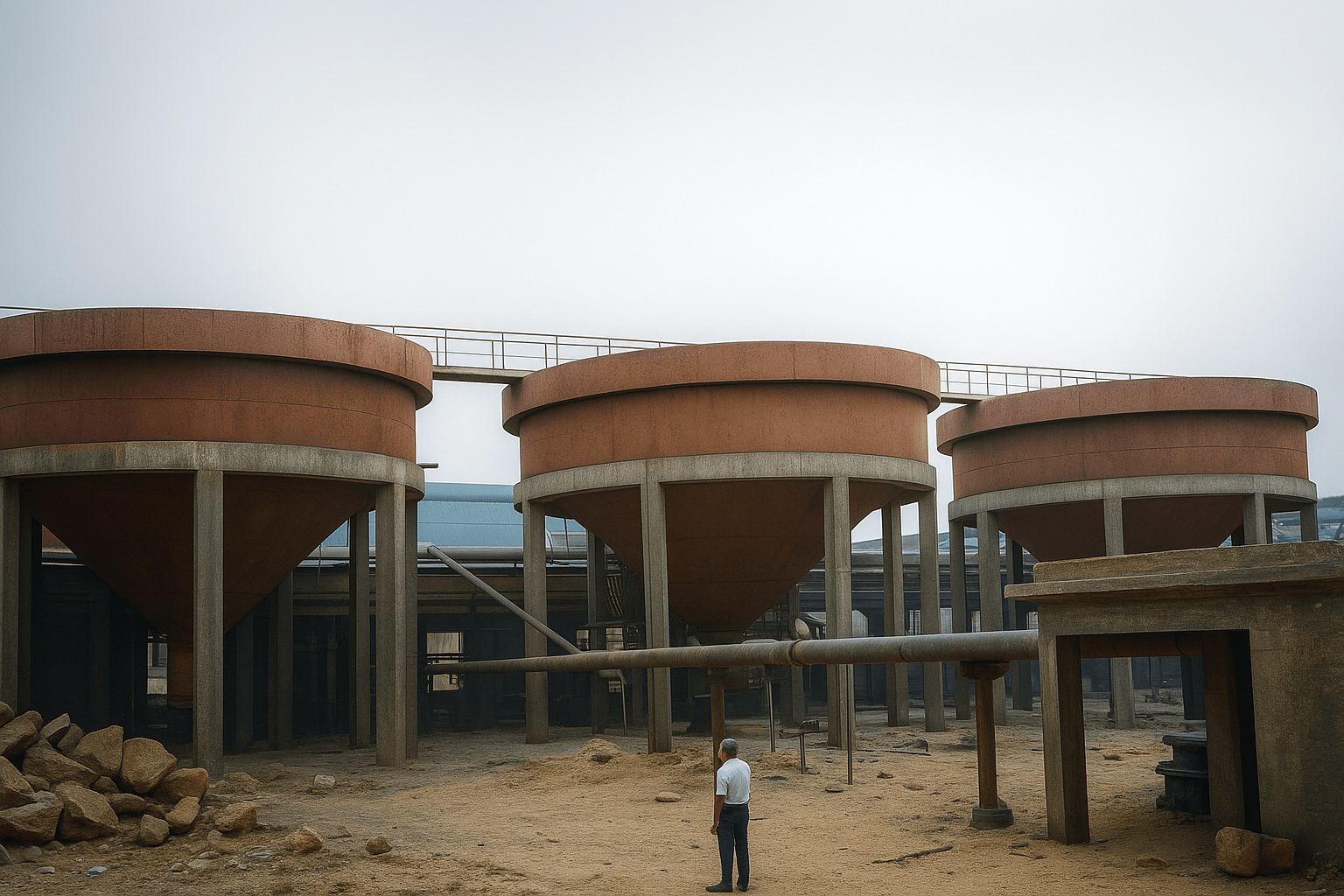

Amria Silos – 6,000 Ton

Summary:

The Amria Silos, located in the industrial zone near Amreya (Amria), Alexandria, is a specialized grain storage facility with a total capacity of 6,000 tons. Designed to serve Egypt’s agricultural and food processing sectors, this modern silo complex plays a crucial role in the safe storage and handling of grains and oilseeds. It supports both import-export operations and local milling industries by ensuring quality preservation, efficient logistics, and year-round availability of raw materials.

Capabilities:

6,000-Ton Storage Capacity

Engineered steel silos with temperature and moisture control systems to store a variety of grains such as wheat, corn, soybeans, and sunflower seeds.Automated Grain Handling

High-speed loading and unloading systems, including bucket elevators and conveyors, ensuring rapid turnaround and minimal product loss.Quality Preservation

Ventilation and aeration technologies to maintain grain quality, prevent spoilage, and protect against pests or mold.Weighing & Sampling Stations

Integrated truck scales and laboratory testing units for accurate inbound/outbound control and quality analysis.Port Access & Strategic Location

Proximity to Alexandria ports facilitates import/export operations and supports industrial clients in the surrounding area.Supply Chain Efficiency

Seamless integration with logistics networks for reliable distribution to flour mills, oilseed crushers, and feed manufacturers.Compliance & Safety

Operations adhere to food safety, environmental, and structural standards for safe bulk grain storage (ISO/HACCP-compliant).

Cargill Egypt: Advancing Food

and Agricultural Excellence

Summary:

Cargill is a global leader in food, agriculture, nutrition, and industrial products, operating in more than 70 countries. In Egypt, Cargill maintains a strategic presence through its investments in grain handling, oilseed processing, and edible oil refining. The company supports food security, industrial supply chains, and economic development by applying international standards of efficiency, safety, and sustainability to its local operations.

Capabilities:

Grain and Oilseed Trading

Active in the sourcing, import, export, and domestic distribution of grains and oilseeds to serve food processors, feed manufacturers, and refiners.Edible Oil Refining

Ownership and operation of advanced refining facilities, including the Silver Fox Project, for the production of high-quality edible oils used in food and industrial applications.Crushing and Processing Facilities

Local infrastructure for oilseed crushing, integrated with refining and packaging systems to ensure supply chain continuity.Logistics and Storage

Strategic access to ports and inland distribution networks for efficient product handling and delivery across Egypt and neighboring regions.Food Safety and Quality Assurance

Compliance with international standards such as ISO and HACCP, supported by in-house laboratories and quality monitoring systems.Sustainability and Environmental Management

Application of global sustainability practices in local operations, focusing on resource efficiency, waste reduction, and responsible sourcing.B2B Support and Industrial Supply

Tailored solutions for clients in the food, beverage, and feed industries, including formulation support and product customization.

Damietta Port Egypt (Molasse export station)

Summary:

The Molasses Export Station at Damietta Port, Egypt, is a specialized terminal facility dedicated to the storage, handling, and international shipment of molasses, a valuable byproduct of the sugar industry. Strategically located on the Mediterranean coast, the station supports Egypt’s growing agro-industrial export sector by providing efficient bulk liquid handling services, enabling smooth transit to global markets in Europe, Africa, and the Middle East.

Capabilities:

Dedicated Molasses Storage Tanks

High-capacity, temperature-controlled storage tanks designed specifically for molasses, ensuring product integrity and minimizing crystallization or spoilage.Bulk Loading Infrastructure

Equipped with pipeline systems and marine loading arms for fast and hygienic transfer of molasses to tankers and cargo vessels.Strategic Port Access

Direct access to deep-water berths at Damietta Port, allowing the docking of large bulk liquid carriers for international export.Weighing and Quality Control Systems

Integrated weighing bridges, sampling stations, and testing labs to ensure accurate volume measurement and product quality assurance before export.Environmental and Safety Compliance

Adherence to international standards for bulk liquid handling, with spill prevention systems, fire safety protocols, and marine environmental controls.Logistics & Coordination

Seamless coordination with inland sugar factories and exporters for just-in-time delivery and ship-loading efficiency.Export Facilitation

Supports the export of molasses primarily used in animal feed, fermentation, and ethanol production in global markets.

Damietta Silos 7000 Ton

Summary:

The Damietta Silos facility, with a total capacity of 7,000 tons, is a key infrastructure asset located within the strategic Damietta Port area on Egypt’s northern coast. Designed to support the country’s grain supply chain, the facility plays a critical role in the storage, handling, and preservation of imported and locally sourced grains. It serves both the domestic food industry and regional trade through its proximity to maritime routes and industrial zones.

Capabilities:

7,000-Ton Storage Capacity

Engineered steel silo bins equipped with ventilation and environmental control systems to ensure long-term grain preservation.Grain Handling Efficiency

Automated systems for receiving, conveying, drying, and dispatching grain to and from ships, trucks, and railcars.Port Integration

Located within Damietta Port, enabling seamless import/export operations with rapid ship unloading and backloading capabilities.Quality Control & Inspection

On-site laboratory for testing moisture content, foreign matter, grain quality, and compliance with safety standards (ISO, GASC).Types of Grains Handled

Designed to store and handle wheat, corn, soybeans, barley, and other cereals, supporting food processors, mills, and feed producers.Environmental & Safety Systems

Dust filtration, temperature monitoring, and fire suppression systems ensure safe and environmentally responsible operations.Supply Chain Support

Provides stable and secure grain inventory for flour mills, oilseed processors, and feed manufacturers in the Damietta and Nile Delta regions.Logistics Connectivity

Excellent road and port access for efficient distribution to inland destinations and regional export markets.

El Fayoum Company For Sugar Industry

Summary:

El Fayoum Company for Sugar Industry is a key player in Egypt’s agro-industrial sector, specializing in the production of white sugar from sugar beet. Strategically located in the fertile Fayoum region, the company supports national food security by processing locally grown crops into high-quality sugar products. With a commitment to sustainability, efficiency, and modern agricultural integration, the company plays a vital role in Egypt’s sugar supply chain and rural economic development.

Capabilities:

Sugar Beet Processing

High-capacity facilities for washing, slicing, extracting, and refining sugar beet into white sugar, with seasonal production peaks aligned with local harvests.Refined White Sugar Production

Production of food-grade white sugar suitable for direct consumption and industrial food applications, meeting national quality standards.Molasses & Byproduct Recovery

Extraction and handling of molasses, beet pulp, and lime sludge, which are repurposed for animal feed, fermentation, or agricultural use.Modern Quality Control

On-site laboratories for real-time monitoring of sugar purity, color, moisture, and microbiological safety, ensuring compliance with ISO and local food safety requirements.Support for Local Agriculture

Close collaboration with local farmers through seed supply, technical assistance, and guaranteed crop purchase programs.Sustainability & Environmental Practices

Use of water recycling systems, energy-efficient boilers, and waste management initiatives to minimize environmental impact.Storage & Packaging Facilities

Silo storage and packaging lines for both bulk and bagged sugar formats tailored to wholesalers, retailers, and food manufacturers.Logistics & Distribution

Reliable supply chain to serve domestic markets across Upper and Lower Egypt with potential for export in surplus seasons.

Gharably Company for Livestock and Agriculture Development Abo El Matamer Factory

Summary:

The Gharably Company for Livestock and Agricultural Development operates a major integrated facility in Abo El Matamer, Egypt, focused on the processing of animal feed and agricultural products. Serving the livestock, poultry, and farming sectors, the factory plays a vital role in supporting sustainable food production by delivering high-quality feed formulations, raw grain handling, and agricultural value-added services. With advanced manufacturing technology and deep sector experience, the facility supports both national supply chains and rural economic development.

Capabilities:

Animal Feed Production

High-efficiency production lines for poultry, cattle, and fish feed, formulated to meet nutritional requirements and optimize animal performance.Raw Grain Processing

Cleaning, grinding, and blending of grains like corn, soybean meal, bran, and additives for consistent, high-quality feed output.Silos & Storage

Large-capacity grain silos and storage warehouses designed for optimal preservation of raw materials and finished products.Nutritional R&D

In-house technical team and lab support for developing and testing feed formulas in line with modern animal health and productivity standards.Sustainability Practices

Waste reduction, energy-saving equipment, and environmentally responsible operations aligned with green agricultural principles.Farmer & Livestock Support

Technical support and consultation services for farmers, including feeding strategies, animal health guidance, and supply contracts.Distribution & Supply Chain

Reliable logistics network serving local farms, cooperatives, and commercial livestock operations across the region.Compliance & Certification

Production adheres to ISO, feed safety, and veterinary control regulations for traceability and safe animal nutrition.

National Company for Maize Products

Summary:

The National Company for Maize Products (NCMP) is a leading Egyptian manufacturer specializing in the processing of corn (maize) into a wide range of industrial and food-grade products. Located in 10th of Ramadan City, NCMP plays a vital role in Egypt’s agro-industrial sector by supplying key ingredients to industries such as food & beverage, pharmaceuticals, paper, adhesives, and animal nutrition. With a strong commitment to quality, efficiency, and innovation, NCMP is a trusted supplier both locally and across export markets.

Capabilities:

Wet Corn Milling Operations

High-capacity wet milling lines that convert corn into a variety of value-added products such as starch, glucose, fructose, and corn oil.Industrial Starch Production

Supply of native and modified starches used in paper manufacturing, textiles, adhesives, and construction materials.Sweetener Manufacturing

Production of glucose syrup, high fructose corn syrup (HFCS), and dextrose, serving food and beverage manufacturers.Refined Corn Oil

Extraction and refining of edible corn oil for cooking applications and industrial food use.Co-products for Animal Feed

Production of corn gluten meal, corn gluten feed, and steep water, providing high-protein inputs for livestock and poultry feed.Quality Assurance & Food Safety

Compliance with ISO, HACCP, and FSSC standards, with modern labs ensuring product purity, consistency, and traceability.Export-Ready Logistics

Well-developed infrastructure for bulk and packaged exports across Africa, the Middle East, and parts of Europe.Sustainable Practices

Focus on resource efficiency, byproduct recycling, and environmentally responsible operations.

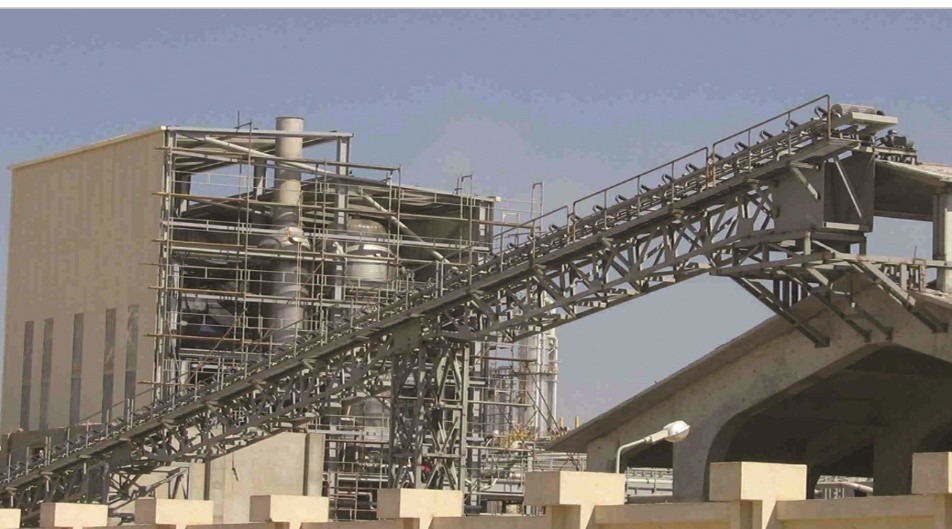

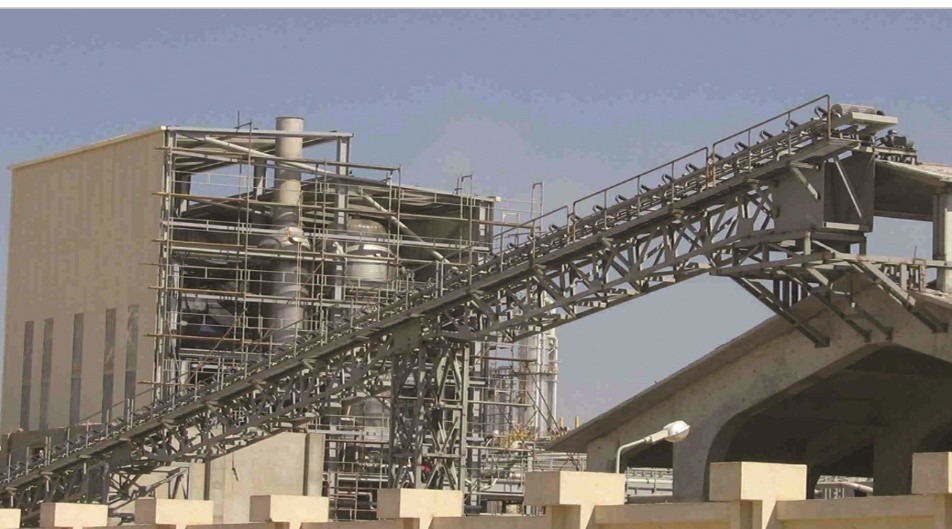

National Vegetables Oil Company - Cargill Silver Fox Project

Summary:

The National Vegetable Oils Company (NVOC), a subsidiary of global agribusiness leader Cargill, plays a strategic role in Egypt’s food and agriprocessing sector. Located in Borg El Arab, Alexandria, the Silver Fox Project is a major expansion of NVOC’s oil refining and packaging capabilities. Designed to meet growing domestic and regional demand, the facility transforms crude vegetable oils into high-quality refined edible oils for retail, industrial, and export markets. Combining advanced processing technologies with strict food safety standards, NVOC reinforces Egypt’s position as a regional hub for food production and supply chain reliability.

Capabilities:

- Edible Oil Refining

High-efficiency refining systems for crude vegetable oils including degumming, neutralization, bleaching, and deodorization, delivering premium food-grade oils. - Bottling & Packaging Operations

Automated filling and packaging lines tailored for PET bottles, jerry cans, and industrial bulk formats, ensuring flexibility for retail and B2B distribution. - Oil Blending & Formulation

Custom oil blends developed to meet specific nutritional, culinary, or industrial needs, backed by Cargill’s global formulation expertise. - Food Safety & Quality Control

On-site laboratories ensure compliance with ISO 22000, HACCP, and Codex Alimentarius standards, with continuous monitoring of purity, shelf life, and microbiological safety. - Energy-Efficient Production

Modern boilers, process heat recovery, and wastewater treatment systems are integrated to reduce energy consumption and environmental impact. - Byproduct Recovery

Utilization of soap stock, spent bleaching earth, and other refining residues for industrial reuse or safe disposal, supporting circular economy goals. - Supply Chain & Distribution

Strategic logistics infrastructure supports reliable delivery across Egypt and export to neighboring regions, with strong warehousing and cold chain options. - Collaboration with Cargill Global Standards

Facility design, operations, and compliance align with Cargill’s international protocols, enabling integration into global food supply chains.

Saudi Egyptian Company for Mineral and Salts

Summary:

The Saudi Egyptian Company for Minerals and Salts (SEMS) is a regional leader in the extraction, processing, and export of high-quality mineral and salt products. Founded through a strategic partnership between Saudi and Egyptian investors, SEMS leverages the rich natural resources of Egypt’s deserts and coastal regions to serve both local industries and global markets. With a focus on industrial-grade and food-grade salt production, alongside other mineral extraction activities, SEMS contributes significantly to sectors such as petrochemicals, food processing, water treatment, and de-icing solutions. The company operates with a commitment to sustainability, quality, and regional development.

Capabilities:

- Salt Production (Industrial & Food Grade)

Large-scale harvesting and refining of salt from solar evaporation ponds and underground sources, processed to meet industrial and edible standards. - Mineral Extraction & Processing

Extraction and classification of key minerals such as gypsum, silica sand, and limestone, used in construction, glass, and chemical industries. - Packaging & Bulk Handling

Modern facilities for packaging salt and mineral products in various forms — from consumer-size bags to bulk containers for export and industrial use. - Quality Assurance

On-site laboratories equipped for chemical and physical analysis ensure products meet international standards (ISO, ASTM, Codex) and customer specifications. - Sustainable Operations

Use of solar energy in evaporation systems, brine recycling, and environmentally conscious extraction practices minimize ecological impact. - Export Capabilities

Strong logistics and port access in the Red Sea and Mediterranean facilitate seamless exports to Gulf countries, Africa, Europe, and Asia. - R&D and Product Customization

Technical teams collaborate with clients to develop customized salt blends or mineral compositions suited to specialized applications. - Strategic Industry Supply

Key supplier to sectors such as oil & gas drilling, food preservation, pharmaceuticals, detergents, and highway maintenance.

Suez co. for fertilizer

Summary:

Suez Company for Fertilizers is a leading Egyptian enterprise specializing in the production of nitrogen-based and compound fertilizers essential for agricultural development. Strategically located near the Suez Gulf with access to major transport and export routes, the company serves both domestic farmers and international markets. Its operations are aligned with national goals for food security and sustainable agriculture, delivering high-efficiency fertilizers that support soil health and crop productivity. Backed by advanced manufacturing systems and strict quality control, Suez Company for Fertilizers is a key contributor to Egypt’s agro-industrial sector.

Capabilities:

- Nitrogen-Based Fertilizer Production

Manufacture of urea, ammonium nitrate, and ammonium sulfate fertilizers, with scalable production capacity to meet seasonal demand. - NPK Compound Fertilizers

Blending and granulation facilities for multi-nutrient fertilizers tailored to different crop and soil requirements. - Quality Assurance & Compliance

Laboratories and technical units ensure chemical balance, nutrient ratios, and granule quality in compliance with ISO, FAO, and local agricultural standards. - Bulk Handling & Packaging

Flexible packaging lines provide fertilizers in various formats — bags, bulk containers, and pallets — for farmers, wholesalers, and international shipping. - Export Operations

Proximity to Suez Port enables efficient logistics and fertilizer export to Africa, the Middle East, and Europe. - Agro-Technical Support

Support for agricultural communities through field trials, fertilization guidelines, and crop-specific nutrient recommendations. - Sustainable Practices

Water and energy optimization, emissions control, and waste recycling programs reduce the environmental impact of fertilizer production. - Research & Development

Ongoing R&D for developing slow-release and environmentally adaptive fertilizer formulas suited to arid and semi-arid regions.

Sugar Co. - Kom Embo factory (Vinas Treatment Plant)

Summary:

The Sugar Company – Kom Embo Factory, located in Upper Egypt, is a major player in the Egyptian sugar industry, with a specialized focus on processing sugar cane into high-purity white sugar. The factory includes the Vinas Treatment Plant, which is dedicated to the handling, treatment, and valorization of sugar production byproducts—particularly vinasse (vinas), a liquid waste from ethanol fermentation. This advanced facility reflects the company’s commitment to sustainable manufacturing and environmental protection. By integrating efficient waste treatment with sugar production, the Kom Embo site supports national agricultural output while reducing its ecological footprint.

Capabilities:

- Sugar Cane Processing

Large-scale facilities for the extraction, clarification, evaporation, and crystallization of sugar from locally grown cane during harvest season. - White Sugar Production

Production of food-grade white sugar meeting Egyptian and international standards for retail and industrial applications. - Vinas Treatment & Valorization

Advanced treatment plant for vinasse, reducing organic load and transforming waste into biofertilizer, animal feed additives, or inputs for biogas generation. - Molasses Recovery

Recovery and processing of molasses for use in fermentation, livestock feed, or export. - Environmental Compliance

Wastewater treatment systems and emissions control units ensure compliance with national environmental regulations and reduce water consumption. - Support for Sugarcane Farmers

Partnership programs with local farmers through input supply, technical training, and guaranteed purchase contracts. - Byproduct Utilization

Integrated use of bagasse (sugarcane fiber) for energy generation or industrial applications. - Laboratory & Quality Control

On-site lab facilities ensure continuous monitoring of sugar purity, moisture, and microbiological safety, aligned with ISO standards.

Sugar company and integrated industries

Summary:

Sugar Company and Integrated Industries is a cornerstone of Egypt’s agro-industrial sector, with a legacy in sugar manufacturing and a focus on full-cycle industrial integration. The company operates across the entire value chain — from cultivating and sourcing sugarcane and sugar beet to producing refined sugar and utilizing every byproduct through integrated industrial systems. Located in strategic agricultural regions, the company not only meets national food and energy demands but also supports rural economies and environmental sustainability. With modern infrastructure and an experienced workforce, the company is a leader in efficient, responsible, and high-capacity sugar production.

Capabilities:

- Sugar Cane & Beet Processing

Industrial-scale operations for extracting and refining sugar from both cane and beet, ensuring year-round production. - Refined Sugar Production

Manufacturing of high-quality white sugar for retail, wholesale, and food industry use, complying with Egyptian and international standards. - Byproduct Integration

Full utilization of molasses, bagasse, vinasse, and beet pulp for ethanol production, energy generation, animal feed, and compost. - Energy Co-Generation

Use of bagasse and biomass to produce steam and electricity for plant operations, enhancing energy efficiency and reducing external dependency. - Fertilizer & Bio-Products

Production of organic fertilizers and industrial inputs from sugar byproducts, supporting circular economy principles. - Environmental Stewardship

Advanced water recycling, emissions control, and solid waste management systems to reduce environmental impact. - Farmer Support & Integration

Long-term contracts and technical assistance for local farmers, ensuring supply stability and agricultural development. - Laboratory Testing & Quality Control

Continuous product testing in on-site labs to monitor sugar purity, microbiological safety, and compliance with ISO and food safety standards. - Logistics & Distribution

An established supply network serving national markets and select regional export destinations.

Uni Lever Egypt Detergent Plant

Summary:

Unilever Egypt’s Detergent Plant is a leading manufacturing hub in the region for home care products, specializing in the production of powdered and liquid detergents. Strategically located to serve both domestic and export markets, the facility is a vital part of Unilever’s global supply chain. The plant reflects Unilever’s global standards in sustainability, automation, and innovation, with a strong focus on product quality, environmental performance, and operational efficiency. Unilever’s Egypt operations contribute significantly to local employment and industrial development, while offering world-renowned brands trusted by millions of households

Capabilities:

- Powder & Liquid Detergent Production

High-speed production lines for a wide range of detergent formats, including powders, gels, and concentrated liquids for various cleaning applications. - Global Brand Manufacturing

Local production of internationally recognized Unilever brands such as OMO, Surf, and Comfort, ensuring consistent quality and brand integrity. - Formulation & Innovation

R&D-backed formulation expertise for stain removal, fragrance enhancement, and environmental safety, tailored to local water conditions and consumer preferences. - Sustainable Manufacturing

Adoption of renewable energy, water reuse systems, and zero-waste-to-landfill practices aligned with Unilever’s global sustainability targets. - Packaging & Private Label

Automated packaging lines with options for both branded and private-label products, in various volumes and configurations. - Quality Assurance Systems

On-site quality labs and compliance with ISO, GMP, and Unilever’s global quality protocols to ensure safety, consistency, and performance. - Workforce Development

Ongoing training, safety programs, and inclusion initiatives for a skilled, engaged, and empowered local workforce. - Distribution & Export

Integrated logistics and supply chain solutions to serve the Egyptian market and export to Africa, the Middle East, and Europe.